Why Our Capes Are Made in Fall River?

We're happy to report that our capes are actively used in cities all over the world. Our customers seem to be unusually comprised of architects, librarians, astrophysicists, writers and other creative sorts. We hear from lots of them. We see a correlation with their appreciation of open spaces, a good walk and smart design lines. A healthy outlook toward rain, nature and the environment are further distinguishing characteristics of the people we meet.

We like to think our customers appreciate our attention to detail. That's a comprehensive approach we take with our outerwear. And it's a big benefit of our close partnership with talented garment workers in nearby Fall River, Massachusetts. It's a good New England collaboration.

Disciplined processes and methods are employed here with every cape and garment. This is one of the few facilities in the US experienced in seam-sealing — that’s a critical skill for well-designed rainwear. Panels are cut precisely, tightly sewn by skilled hands, and artfully constructed for dependable performance in varying weather conditions. The hood is optimized for fit and peripheral vision with a sturdy brim. Some capes have armholes with magnetic closures that snap shut automatically.

Coincidentally, you'll note that engineering happens to derive from the Latin ingenium, meaning "cleverness."

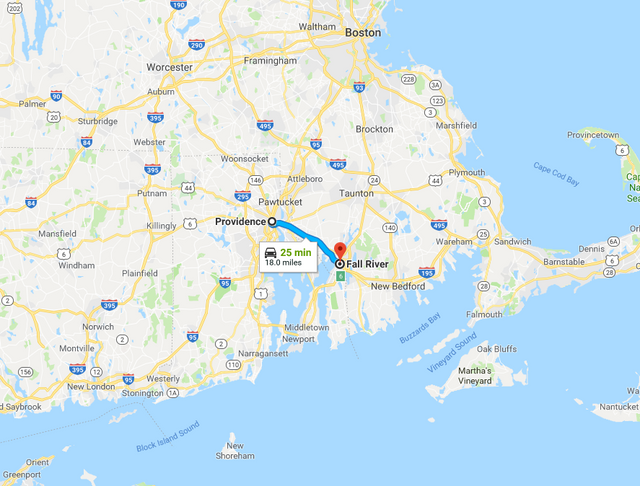

Our apparel benefits from a fast turnaround. It's a short hop for us to Fall River and back to the Creative Capital. We have all the usual global collaboration tools, but you can’t beat the efficiency of a prototype in your hands that afternoon. We get extra time to perfect designs, to evaluate small runs, and to nip problems in the bud.

We’re focused on performance plus style. That means creating a garment that’s distinctive and stands up to the weather. Every component matters. Aesthetics count. An impressive zipper can inspire an entire garment by its teeth or its color. But the zipper’s grip, its performance in rain and dependability counts too. Pockets are resized, hoods are deconstructed, improvements to every detail come from the close collaboration of Fall River production and Providence design.

We work closely together and develop a healthy appreciation for collaboration and craftsmanship. There’s a personal pride in the way things are done. Triple-stitched anchors for thumb loops are tugged and tested. Every component, seam, hood and finished garment is inspected. Good teamwork enables us to set high quality standards for ourselves.

Formerly spindle city, Fall River has a historical legacy of skilled garment workers. While the textile industry has moved on, it’s left an impact on this city’s people and culture. Twenty miles away from Providence, these folks are our neighbors. We appreciate their contribution to the neighborhood, their expertise, and can-do spirit. Globally speaking, we all have a Fall River, neighbors helping neighbors.

We're thankful for good neighbors. Working together sure makes things a lot better around here. It's a clever approach to sustainable apparel manufacturing that seems to apply all over the world.

We like to think our customers appreciate our attention to detail. That's a comprehensive approach we take with our outerwear. And it's a big benefit of our close partnership with talented garment workers in nearby Fall River, Massachusetts. It's a good New England collaboration.

Why Fall River? 5 Smart Benefits for your Consideration.

#1 Engineering

Disciplined processes and methods are employed here with every cape and garment. This is one of the few facilities in the US experienced in seam-sealing — that’s a critical skill for well-designed rainwear. Panels are cut precisely, tightly sewn by skilled hands, and artfully constructed for dependable performance in varying weather conditions. The hood is optimized for fit and peripheral vision with a sturdy brim. Some capes have armholes with magnetic closures that snap shut automatically.

Coincidentally, you'll note that engineering happens to derive from the Latin ingenium, meaning "cleverness."

Customer Benefits: Well-made apparel

#2. Logistics

Our apparel benefits from a fast turnaround. It's a short hop for us to Fall River and back to the Creative Capital. We have all the usual global collaboration tools, but you can’t beat the efficiency of a prototype in your hands that afternoon. We get extra time to perfect designs, to evaluate small runs, and to nip problems in the bud.

Customer Benefits: Smart ideas materialize faster

#3. Design

We’re focused on performance plus style. That means creating a garment that’s distinctive and stands up to the weather. Every component matters. Aesthetics count. An impressive zipper can inspire an entire garment by its teeth or its color. But the zipper’s grip, its performance in rain and dependability counts too. Pockets are resized, hoods are deconstructed, improvements to every detail come from the close collaboration of Fall River production and Providence design.

Customer benefits: Sharp-looking outerwear performance

#4. Quality

We work closely together and develop a healthy appreciation for collaboration and craftsmanship. There’s a personal pride in the way things are done. Triple-stitched anchors for thumb loops are tugged and tested. Every component, seam, hood and finished garment is inspected. Good teamwork enables us to set high quality standards for ourselves.

Customer benefits: Apparel that is made to last

#5. Neighbors

Formerly spindle city, Fall River has a historical legacy of skilled garment workers. While the textile industry has moved on, it’s left an impact on this city’s people and culture. Twenty miles away from Providence, these folks are our neighbors. We appreciate their contribution to the neighborhood, their expertise, and can-do spirit. Globally speaking, we all have a Fall River, neighbors helping neighbors.

Customer benefits: Support for local garment workers

We're thankful for good neighbors. Working together sure makes things a lot better around here. It's a clever approach to sustainable apparel manufacturing that seems to apply all over the world.